Chip decapsulation technology is an important step in the integrated circuit manufacturing process. Its purpose is to remove the packaging material or structure from the chip for further testing, repair, or re-encapsulation. Here are several common chip decapsulation technologies and their comparisons, as well as the latest developments:

Mechanical decapsulation technology: Mechanical decapsulation is one of the most traditional methods, using mechanical tools such as blades or cutting machines to cut or peel off the packaging material from the chip. This method is simple and direct but may impose mechanical and thermal stresses on the chip, making it prone to damage. Additionally, mechanical decapsulation is only suitable for one-time decapsulation and not suitable for applications that require repeated encapsulation.

Thermal decapsulation technology: Thermal decapsulation technology utilizes thermal stress or thermal expansion principles to remove the packaging material. Common methods include thermal delidding and thermal cutting. Thermal delidding uses high temperatures to make the packaging material brittle, which is then removed mechanically or by airflow. Thermal cutting involves localized heating and application of force to cut the packaging material. These methods reduce mechanical stresses but can still impose thermal stresses and damage to the chip.

Chemical decapsulation technology: Chemical decapsulation technology utilizes chemical solvents or etchants to corrode or dissolve the packaging material. These solvents or etchants have low corrosion rates on the chip itself, but careful handling is still required to avoid damage to the chip. Chemical decapsulation technology has advantages in high-density packaging and complex structured chips since it allows precise control of the decapsulation process.

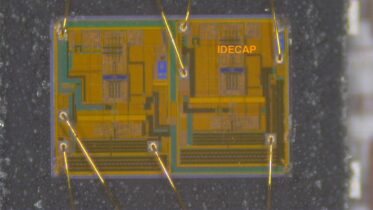

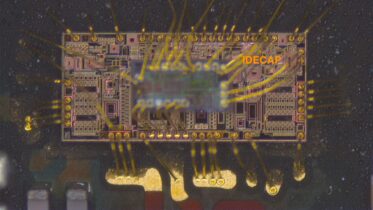

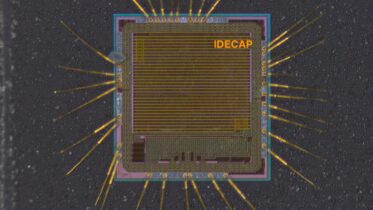

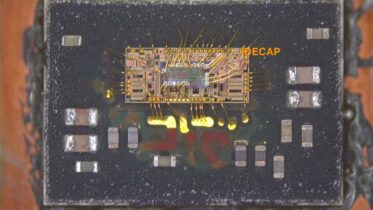

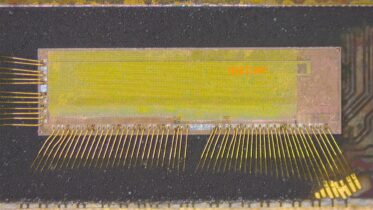

Laser decapsulation technology: Laser decapsulation technology uses laser beams to evaporate or cut through the packaging material. The high energy and focusing capability of lasers enable precise decapsulation operations with minimal damage to the chip. Laser decapsulation technology is particularly suitable for high-density packaging and microchips. However, laser equipment is costly and requires precise control and professional operation.

The latest developments include the following aspects:

- High precision and efficiency: With the reduction in chip size and increase in density, decapsulation technology requires higher precision and efficiency. New decapsulation equipment and processes are continuously being developed to meet this demand.

- Non-contact decapsulation technology: To reduce mechanical stress and damage to chips, researchers are exploring non-contact decapsulation techniques such as plasma decapsulation. These technologies utilize physical force fields on the packaging material without direct contact with the chip.

- Automation and intelligence: To improve production efficiency and reduce operational errors, automated and intelligent decapsulation equipment is gaining attention. Technologies such as machine vision, machine learning, and artificial intelligence are being applied to control and optimize the decapsulation process.

- Environmentally friendly: With an increasing awareness of environmental protection, researchers are focused on developing more environmentally friendly decapsulation technologies. For example, using low-pollution solvents or adopting recyclable materials to reduce environmental impact.In summary, chip decapsulation technology is continuously evolving to meet the requirements of high precision, efficiency, non-contact operation, and environmental friendliness. With the advancement of technology, ICDECAP LIMITED, an innovative company, combines laser and plasma technologies to achieve a balance between efficiency and decapsulation results. For standard chip decapsulation, they have developed models such as the iLPlasma laser plasma decapsulation machine (laser and plasma integrated), iPlasma plasma decapsulation machine, and iLaser laser decapsulation machine. These machines allow decapsulation to be done within minutes without the use of any acids. Feel free to contact ICDECAP LIMITED for further consultation and information.

中文

中文